Pipeline infrastructure in the United States supports energy delivery, water supply, and industrial operations across vast distances. Maintaining these critical networks requires specialized tools and technologies that ensure continuous operation while minimizing risk. Xinyu Feihu Pipeline Technical Equipment Co., Ltd. delivers advanced solutions for live pipeline maintenance, making it a trusted provider of Pipeline Plugging Equipment in United States. Their equipment allows oil & gas producers, municipal utilities, petrochemical facilities, and construction companies to carry out essential maintenance without costly shutdowns.

Why Pipeline Plugging Equipment is Essential

Pipelines transport oil, natural gas, water, and chemicals under high pressure, making maintenance a challenging task. Pipeline Plugging Equipment in United States enables operators to perform live maintenance, leak repair, and modifications without interrupting service. This capability is essential for avoiding operational delays and minimizing financial losses. High-quality equipment ensures that refineries, distribution networks, and municipal systems can maintain reliability while protecting personnel and the environment.

The ability to isolate sections of a pipeline safely prevents unnecessary shutdowns, reduces operational downtime, and ensures uninterrupted service. Companies across the United States depend on these technologies to maintain critical infrastructure efficiently and securely.

Types of Pipeline Plugging Equipment Offered

Xinyu Feihu provides a range of solutions designed to meet diverse industrial needs. Their Pipeline Plugging Equipment in United States portfolio includes:

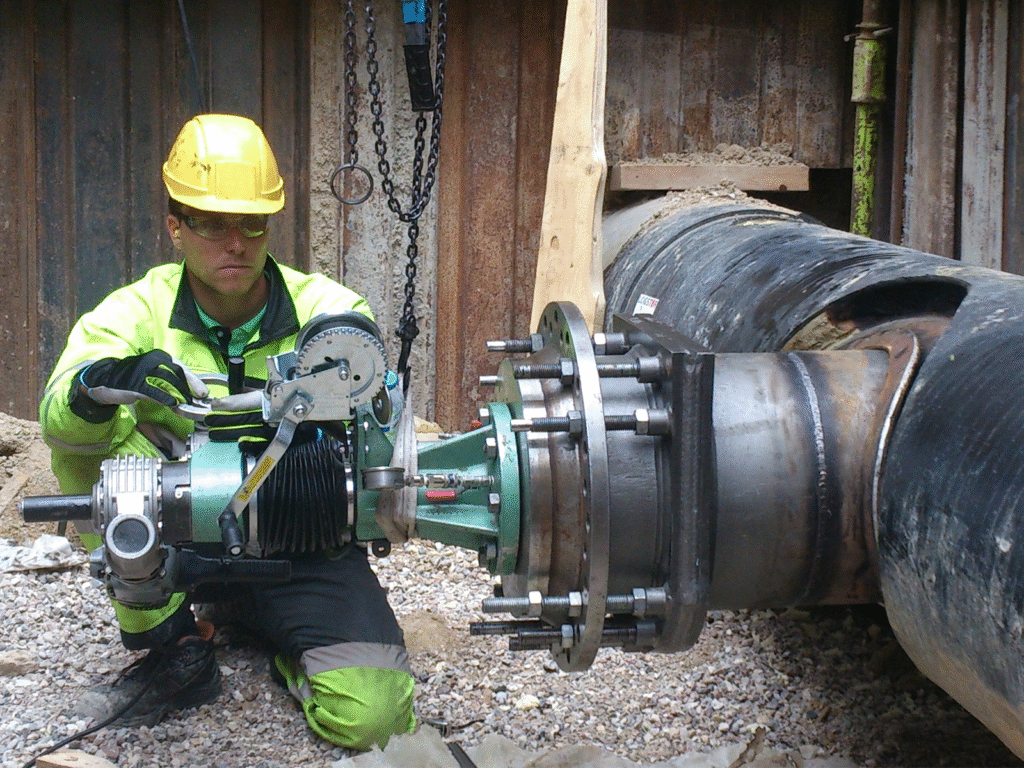

- Hot Tapping Machines – These machines perform under-pressure drilling to add new branches to pipelines without stopping the system. Hot tapping is widely used in oil & gas, water distribution, and industrial projects to expand capacity or connect additional pipelines.

- Hydraulic Plugging Machines – Designed for secure pipeline isolation, these machines can safely stop the flow of fluids in pipelines of various diameters. They are suitable for high-pressure systems in refineries, gas distribution, and municipal water networks.

- Electrofusion Tapping Saddles – Used to create robust branch connections in PE pipelines, these saddles are essential for utility upgrades and industrial installations. They provide strong, leak-proof connections under operational conditions.

- Subsidiary Devices – Accessories such as line stopping tools, leak repair kits, and installation components enhance the functionality of primary plugging equipment. They ensure maintenance operations are completed efficiently and safely.

Applications Across United States Industries

Pipeline Plugging Equipment in United States serves multiple sectors, each with specific requirements for safety, precision, and reliability.

- Oil & Gas Pipelines – Operations in the Permian Basin, Gulf Coast, and other energy hubs rely on live pipeline maintenance to prevent service disruptions. Xinyu Feihu’s equipment supports expansions, repairs, and isolation tasks critical to energy delivery.

- Municipal Water Networks – Cities like New York, Los Angeles, and Chicago benefit from line-stopping and leak repair solutions, enabling maintenance without interrupting water supply to residents and businesses.

- Petrochemical Plants and Refineries – Continuous operations are essential for these facilities. Pipeline Plugging Equipment in United States allows maintenance teams to perform isolation and hot tapping safely, reducing downtime and operational risk.

- Construction and Utility Maintenance Projects – When infrastructure upgrades or expansions are required, these tools allow contractors to work on live pipelines, reducing project timelines and maintaining service for local communities.

Safety and Compliance Considerations

High-pressure pipelines pose inherent risks, making safety a priority. Xinyu Feihu designs all Pipeline Plugging Equipment in United States to meet rigorous standards, including ISO 9001, ISO 14001, and ISO 45001 certifications. These standards ensure that equipment is safe, reliable, and environmentally responsible.

Operators can perform maintenance on high-pressure lines without compromising safety. The hydraulic systems are engineered to handle extreme conditions, while hot tapping machines provide precise drilling with minimal risk of leaks. Regulatory compliance is essential, and Xinyu Feihu ensures that their equipment aligns with federal, state, and industry safety requirements.

Cost Efficiency and Operational Benefits

Pipeline maintenance can be expensive, particularly if systems must be shut down for repairs. Pipeline Plugging Equipment in United States reduces these costs by allowing live maintenance. Avoiding full system shutdowns prevents lost production and minimizes downtime, directly impacting a company’s bottom line.

Operational efficiency improves as maintenance teams can isolate sections of pipelines quickly and safely. Projects that would take days or weeks can often be completed in hours. Long-term savings extend beyond immediate operational costs, as equipment reliability reduces the need for frequent repairs or replacements.

Why Choose Xinyu Feihu for US Projects

Xinyu Feihu has more than 20 technical patents and a proven track record of global projects. Their expertise ensures that Pipeline Plugging Equipment in United States delivers dependable performance across multiple sectors. The company provides technical support, training, and consultation to ensure clients can operate the equipment effectively and safely.

US companies benefit from a partner that understands both the technical and regulatory challenges of pipeline maintenance. Xinyu Feihu combines advanced technology with hands-on expertise to deliver solutions that meet high operational standards and tight project timelines.

Case Studies of Pipeline Plugging Equipment in United States

Several projects illustrate the effectiveness of Xinyu Feihu’s equipment. In Texas, live isolation of oil pipelines allowed a refinery to complete critical maintenance without halting production. In New York, municipal water lines were repaired using line-stopping devices, ensuring uninterrupted water service to thousands of residents. In petrochemical facilities along the Gulf Coast, hot tapping enabled the addition of new process lines without halting operations, saving significant time and cost. These examples demonstrate how Pipeline Plugging Equipment in United States supports operational reliability and efficiency across industries.

Takeaway

Pipeline Plugging Equipment in United States is a critical investment for companies seeking reliable, efficient, and safe pipeline maintenance. Xinyu Feihu’s advanced technologies, global expertise, and dedicated support help US industries maintain energy, water, and industrial systems with confidence. Businesses across the nation can improve operational efficiency, reduce costs, and ensure uninterrupted service by adopting Xinyu Feihu’s pipeline plugging solutions. Contact Xinyu Feihu for consultations and discover how their equipment can support your pipeline projects safely and effectively.

Frequently Asked Questions

1. What is Xinyu Feihu’s experience in the United States?

Xinyu Feihu has over 20 years of experience in pipeline plugging equipment and has successfully supported projects across US industries, including oil & gas, municipal utilities, and petrochemical facilities.

2. How can US companies purchase or consult on pipeline plugging equipment?

Businesses can contact Xinyu Feihu directly for consultations, project assessments, and quotations. The company provides full support for equipment selection, installation, and operation.

3. How does Xinyu Feihu ensure safety during high-pressure pipeline maintenance?

All equipment meets ISO-certified management standards, undergoes rigorous testing, and is designed for high-pressure operations. Training and technical guidance are provided to ensure safe and efficient use.

4. What types of pipelines can the equipment handle?

Xinyu Feihu’s equipment supports oil, natural gas, water, and chemical pipelines of varying diameters and materials, including steel, PE, and composite pipelines.

5. Why is live pipeline maintenance important?

Live pipeline maintenance reduces downtime, minimizes operational costs, and ensures continuous delivery of essential services such as energy and water. It allows companies to perform critical tasks without interrupting service.