Line plugging technology has significantly advanced over the years, playing a crucial role in industries that rely on pipeline infrastructure. A line plugging machine manufacturer is responsible for developing high-performance equipment that allows businesses to conduct maintenance, repairs, and modifications without shutting down entire pipeline systems. With continuous advancements in technology, the efficiency, safety, and sustainability of line plugging solutions have improved drastically. This article explores the evolution of line plugging technology and provides insights from a top line plugging machine manufacturer on the latest innovations in the industry.

Understanding Line Plugging Technology

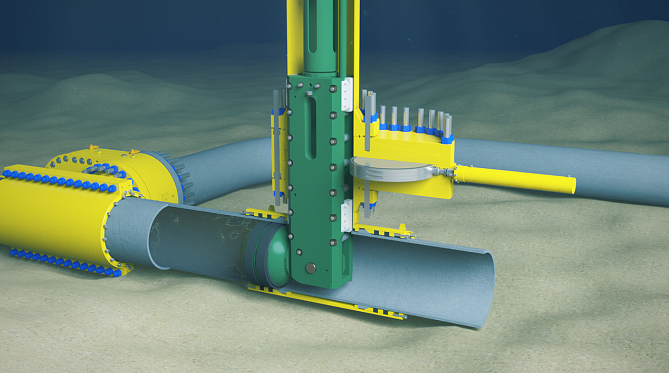

A line plugging machine manufacturer designs and produces specialized equipment that enables the temporary isolation of pipeline sections while keeping the rest of the system operational. This technology is essential in industries such as oil and gas, water utilities, and chemical processing, where unplanned shutdowns can lead to significant losses. Modern line plugging machines provide precise pressure control, leak prevention, and long-term reliability. The expertise of a leading line plugging machine manufacturer ensures that these systems are engineered to withstand high pressures and extreme temperatures, meeting the highest industry standards.

The Early Days of Line Plugging

Before the advancements introduced by today’s line plugging machine manufacturer, early pipeline maintenance relied on rudimentary mechanical seals and manual intervention. These outdated techniques often resulted in leaks, system failures, and increased downtime. Industries had to perform costly shutdowns to repair pipeline sections, leading to production losses. The absence of sophisticated materials and pressure-resistant solutions made it challenging to achieve a safe and effective pipeline isolation. However, as industrial demands increased, the need for a reliable line plugging machine manufacturer became evident, driving the development of more advanced plugging solutions.

Major Milestones in Line Plugging Advancements

The development of modern line plugging technology can be attributed to continuous research and innovation by leading line plugging machine manufacturers. Some of the major milestones in this field include:

- Mechanical Line Plugging: Introduction of mechanical plugs with enhanced sealing capabilities, reducing leakage risks.

- Inflatable Plugging Systems: Development of high-strength inflatable plugs to accommodate varying pipe diameters and pressures.

- Advanced Sealing Materials: Use of heat-resistant and chemically stable materials to improve the durability of plugs.

- Automated Line Plugging Machines: Integration of digital controls, automation, and real-time monitoring for improved precision and safety.

Each of these advancements has been spearheaded by an expert line plugging machine manufacturer, ensuring that businesses can maintain pipeline integrity without compromising productivity.

Cutting-Edge Technologies in Modern Line Plugging

Today’s leading line plugging machine manufacturers have introduced state-of-the-art innovations that enhance the efficiency and safety of pipeline isolation. Some of the most notable advancements include:

- Smart Sensors and Remote Monitoring: The use of IoT-enabled sensors allows operators to monitor pressure, temperature, and plug integrity in real time.

- AI-Driven Predictive Maintenance: AI algorithms help predict potential pipeline issues before they occur, reducing unplanned maintenance costs.

- Eco-Friendly Plugging Solutions: Manufacturers are now developing biodegradable and sustainable plugging materials to minimize environmental impact.

- Enhanced Safety Features: Modern machines include automated pressure regulation, emergency shutoff systems, and compliance with international safety standards.

A top line plugging machine manufacturer plays a critical role in developing and refining these technologies to meet the growing needs of various industries.

Insights from a Top Manufacturer

Industry leaders in line plugging technology, such as a reputable line plugging machine manufacturer, have a unique perspective on the evolution of this field. Based on expert insights, some key factors driving innovation include:

- Increased demand for efficiency: Companies seek ways to minimize operational disruptions while maintaining pipeline performance.

- Stricter regulations: Compliance with environmental and safety standards has pushed manufacturers to create more advanced and sustainable solutions.

- Technological advancements: The integration of AI, automation, and smart sensors has revolutionized line plugging capabilities.

- Customised solutions: Businesses now require tailored plugging systems designed for specific industry applications.

A leading line plugging machine manufacturer continuously invests in research and development to address these evolving challenges and provide the most effective solutions.

Benefits of Advanced Line Plugging Technology

The latest innovations from top line plugging machine manufacturers offer numerous benefits, including:

- Minimized Downtime: Advanced plugging machines allow maintenance teams to isolate pipeline sections without shutting down the entire system.

- Enhanced Worker Safety: Automated and remotely operated plugging solutions reduce the need for direct human intervention in hazardous environments.

- Cost Savings: High-efficiency plugging machines reduce maintenance and operational costs by preventing unplanned shutdowns.

- Environmental Compliance: Sustainable materials and precision engineering help industries adhere to environmental regulations while maintaining pipeline integrity.

These advantages highlight the critical role of a reliable line plugging machine manufacturer in supporting industrial operations worldwide.

The Future of Line Plugging Technology

Looking ahead, the future of line plugging technology will continue to be shaped by technological advancements and industry demands. A leading line plugging machine manufacturer is expected to focus on:

- AI and Machine Learning Integration: Advanced data analytics will improve predictive maintenance and fault detection.

- Robotic Plugging Solutions: The development of autonomous robotic systems capable of executing pipeline plugging with minimal human involvement.

- More Sustainable Materials: The shift towards biodegradable and environmentally friendly plugging compounds.

- Increased Automation and Remote Operation: Fully automated systems that allow for precise plugging with minimal manual adjustments.

As technology progresses, businesses will continue to rely on innovative solutions from top line plugging machine manufacturers to ensure seamless and efficient pipeline maintenance.

Takeaway

The evolution of line plugging technology has transformed how industries maintain and repair their pipelines, ensuring minimal disruptions and increased safety. Thanks to the continuous efforts of leading line plugging machine manufacturers, businesses now have access to highly efficient, automated, and sustainable plugging solutions. From early mechanical systems to AI-powered innovations, the industry has made significant strides, and the future promises even more groundbreaking advancements. Companies seeking to optimize their pipeline maintenance strategies should consider working with a trusted line plugging machine manufacturer to stay ahead of the curve.

By embracing the latest technologies and industry best practices, organizations can enhance operational efficiency, reduce costs, and meet stringent safety and environmental standards. The role of a top line plugging machine manufacturer remains crucial in shaping the future of pipeline maintenance, ensuring that businesses continue to operate smoothly and efficiently.